ERVs: a solution for energy waste

In commercial buildings, HVAC systems account for 60% of energy consumption with a significant portion lost during ventilation.

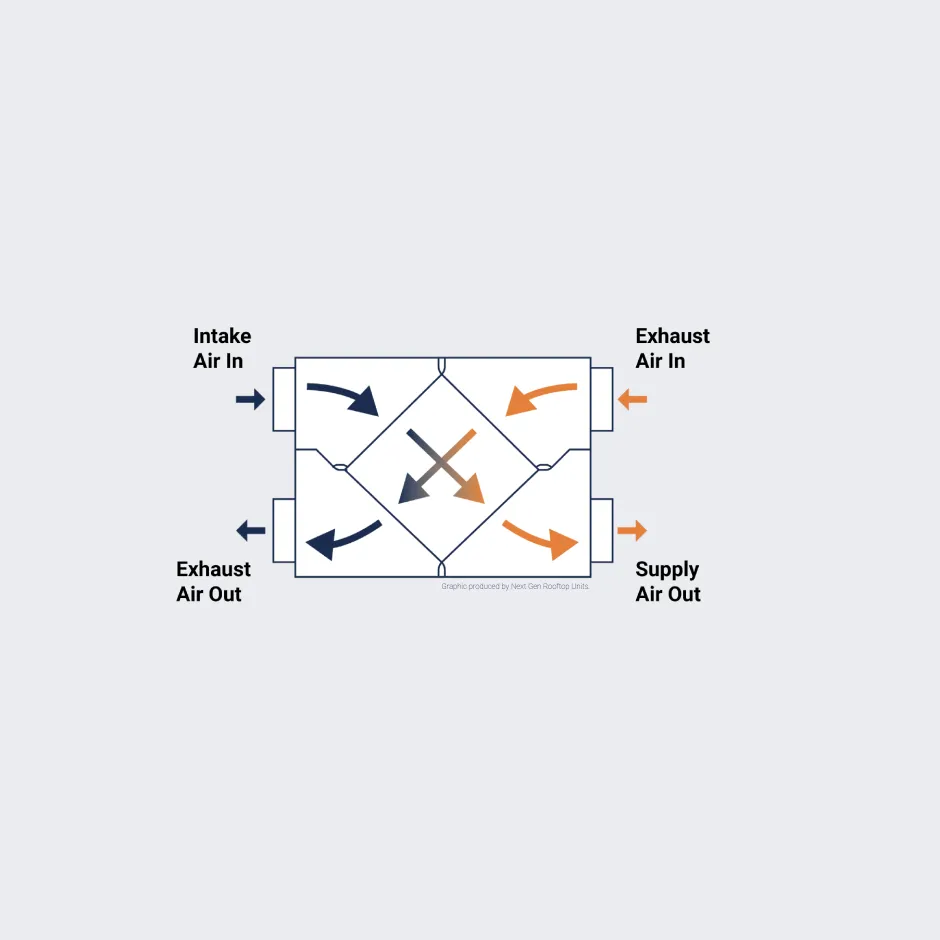

Energy recovery ventilators (ERVs) offer a solution to prevent energy waste, by recovering heat and energy that would otherwise be lost to exhaust air. ERVs save both energy and money by preventing energy loss during ventilation. Some rooftop units (RTUs) are manufactured with integrated ERVs, but most ERVs are post-installed as a bolt-on application.

Why ERVs on RTUs?

- RTUs ventilate in addition to heating and conditioning air. The exhaust air that is vented out is conditioned to the right temperature, while bringing in fresh outdoor air that needs to be heated or cooled.

- ERVs use the sensible heat from the exhaust air to bring the outdoor air closer to the desired temperature.

- Unlike heat recovery ventilators (HRVs), ERVs also balance the humidity of the incoming air, which is critical in Minnesota’s humid climate.

- By recovering moisture and heat from exhaust air, ERVs improve comfort, save energy, and reduce utility bills.

Benefits of ERVs on rooftop units

Energy efficiency

- Reduces energy use by 15-25% compared to RTUs without ERVs or HRVs

- Proper installation, commissioning, and maintenance maximizes energy savings

- Recommissioning increases effectiveness by 40%

Effective energy reduction for many building types

- Effective in buildings with ventilation requirements of 18% or more outdoor air like offices, outpatient centers, retail spaces

- Great for buildings with higher outdoor air needs, like schools, healthcare facilities, restaurants, manufacturing facilities

Comfort in our cold climate and high humidity summers

- ERVs balance humidity and adjust intake air to a more comfortable temperature.

- 60%–80% of energy savings from ERVs occur in heating between 12°F–45°F. ERVs are most efficient in cooling above 80°F.